Piping Engineering

BBSD offers piping engineering services for both onshore and offshore plants. The piping engineering services includes but not limited to:

Piping Materials Specification

Plant Layout Design & Piping Routing

Piping Stress Analysis

Piping Materials includes defining material classes, corrosion control strategies, and specifications for pipes, fittings, flanges, valves, and gaskets. For offshore projects, our engineers are familiar with harsh marine environments, high pressures, extreme temperatures, and weight optimization while adhering to codes like ASME, API, and ISO.

Material Selection & Specification for pipes, fittings, flanges, gaskets, valves, and special items

Documentation and Specification Development (PMS, MSD, MRs and Valve Datasheets)

Procurement Support

Coordination & Interface Management

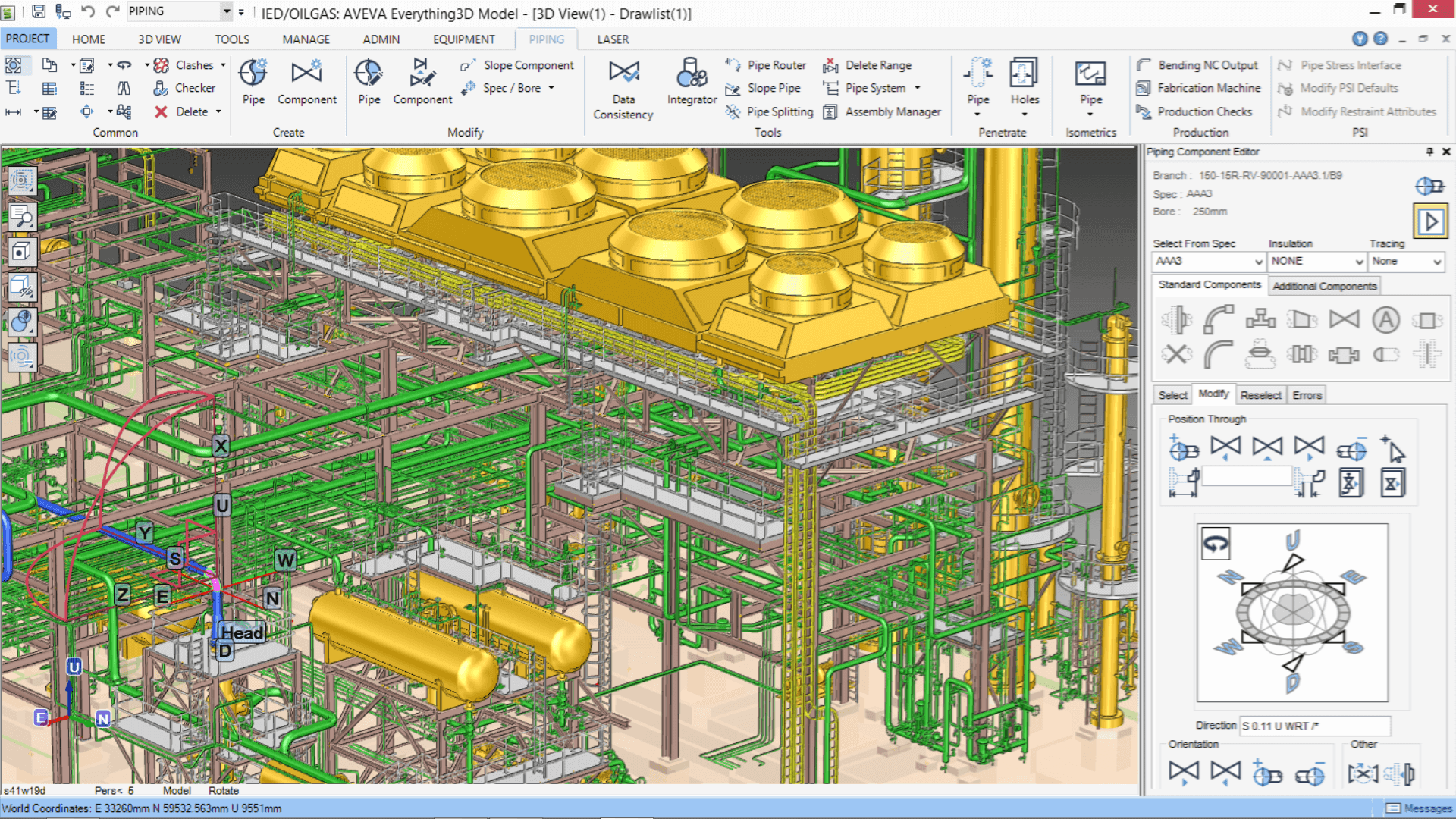

Piping Routing is the pivot discipline for offshore plant design. The piping design focuses on developing efficient, safe, and maintainable piping systems within the limited space of offshore facilities. It involves creating optimized layouts that balance process requirements, safety regulations, structural constraints, and accessibility. BBSD offers design activities from Single Function Module to Entire Plant like Full FPSO Topside.

Plant Layout Development

Pipe Routing Design

3D Modelling using cutting edge tools like E3D and PDMS

Interface and Coordination (Design Review and Clash Check)

Piping Stress discipline ensure that piping systems can safely withstand internal pressures, thermal expansion, dynamic loads, and external forces while meeting code and project requirements. This discipline involves analyzing piping flexibility, support design, and load transfer to equipment and structures using tools like CAESAR II or AutoPIPE. Piping Stress Analysis services includes following but not limited to:

Piping Stress Analysis

Support Design and Optimization

Equipment Nozzle Load Evaluation