Mechanical Engineering

BBSD offers mechanical engineering services for both onshore and offshore plants. The mechanical engineering focuses on the specification, design, selection, and integration of static and rotating equipment to ensure safe, reliable, and efficient operation in harsh offshore environments. Our main services include:

Equipment Design and Specification

Vendor Engagement and Procurement Support

Integration with Plant Layout Design

Equipment Design collects design inputs from Process data sheets and P&ID’s and define design criteria for equipment selection and sizing. The design ensure compliance with standards like ASME Section VIII, API 617, API 650, API 660, API 680, TEMA. BBSD has experiences with following equipment systems:

Static Equipment: Pressure vessels, storage tanks, filters and heat exchangers

Rotating Equipment: Pumps, Compressors, Turbines

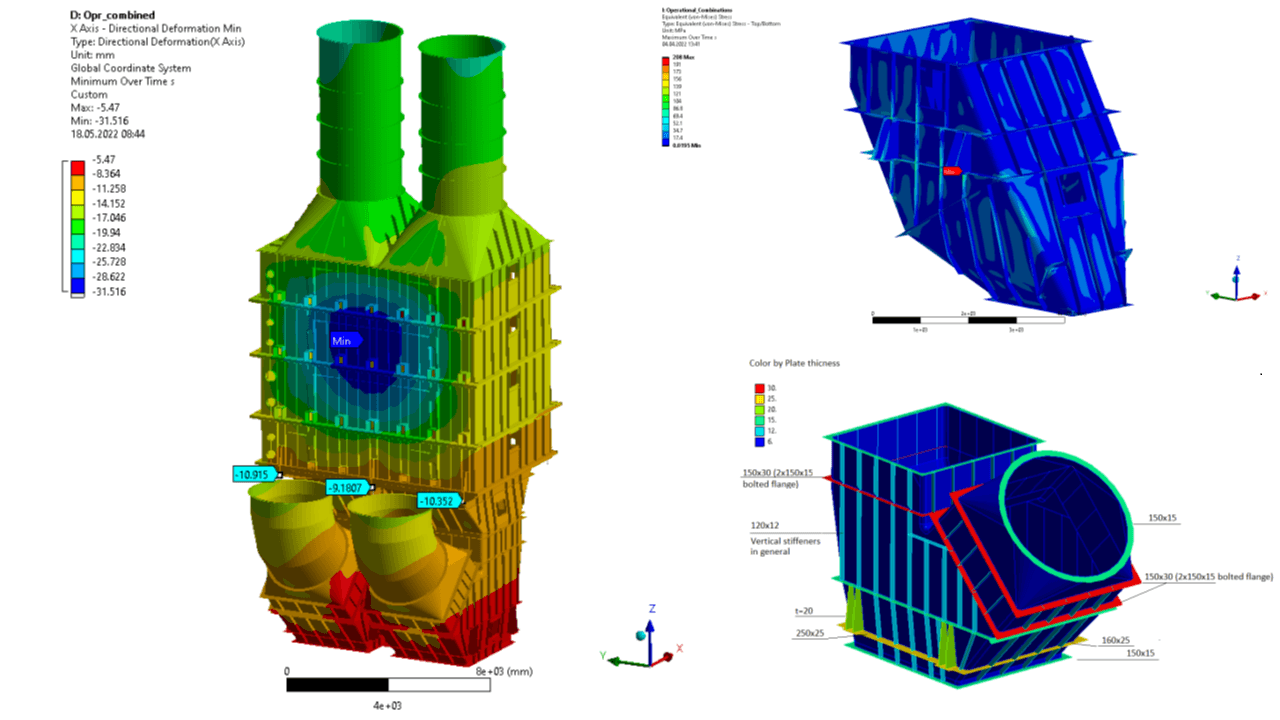

Skid-mounted and packaged units: WHRU & HRSG

Vendor Engagement and Procurement Support with our hands-on dedicated mechanical engineers is the key success for on-time delivery of various equipment. During both project preparation and the execution phase, our engineers will:

Prepare Material Requisitions (MRs) for procurement and conduct technical bid evaluations (TBEs) to select the most suitable vendor

Review and approve vendor drawings, datasheets, and calculations

Coordinate Factory Acceptance Tests (FATs) and witness critical inspections

Integration with Layout is the key for offshore plant design which requires complicated multiciliary coordination with piping layout design, E&I design and Structural Design:

Provide equipment layout guidance to ensure optimized operations and efficient installation.

Work with structural engineers to confirm foundation, skid, and support design

Collaborate with piping teams to verify nozzle loads and thermal expansion allowances

Produce mechanical handling report and layout for plant maintenance and operations